PARAJET

Three years as a product design engineer at Parajet meant equipment design for the adventure aviation market alongside consultancy work for military clientele. FOCUSSED ON POWERED PARAGLIDERS, WHILST BEING Surrounded by sister companies Crighton, Mako and Rotron, producing high performance rotary-engined superbikes, jet-driven surf boards and engines for military aircraft, it was a highly exciting environment to be in.

Parajet, Product Design Engineer, Mar 2020 - Jan 2024

design engineering

industrial design

project management

new supply chains

marketing

UX / UI design

design strategy

brand work

FROM DAY 1, UNDERSTANDING BUSINESS STRATEGY WAS KEY TO DESIGN DIRECTION.

Parajets goal was simple, survive the pandemic and gear up to flourish in the decade following.

-

In sales Parajet faced adversity post coronavirus which could be solved through good design and brand building.

Navigating a market flooded with shed-built custom machines and second hand OEM products meant developing new features with high desirability and real user benefits utilizing production techniques which smaller companies simply couldn't access.

This work would eventually be paired with a rebrand cementing Parajet as a modern industry leader far advanced of it's shed-based roots.

-

Like most companies, COVID negatively impacted supply chains at Parajet, and with an already tightly strained operations team, the design team were drafted in to find resolutions.

Through months of research, meetings, manufacturing communications and prototype reviewing, secondary supply chains were sourced. -

Preparing for potential consumer market instability meant ensuring alternate revenue could be sourced.

Design team time would be split to focus on both consumer product and defence consultancy work, always ensuring work was completed to a standard which would encourage more new projects.

fabrication

injection moulding

rotational moulding

forging

assembly

machining

3D printing

composites

Mav Max (above) was a key part of this strategy, with a new frame ideal for consumer and defence markets

Although joining towards the latter stages of design, developing some components and completing the design for manufacture work on Mav Max was an excellent first project at Parajet. It makes a good example of the kind of work completed on soon to be released next-generation models.

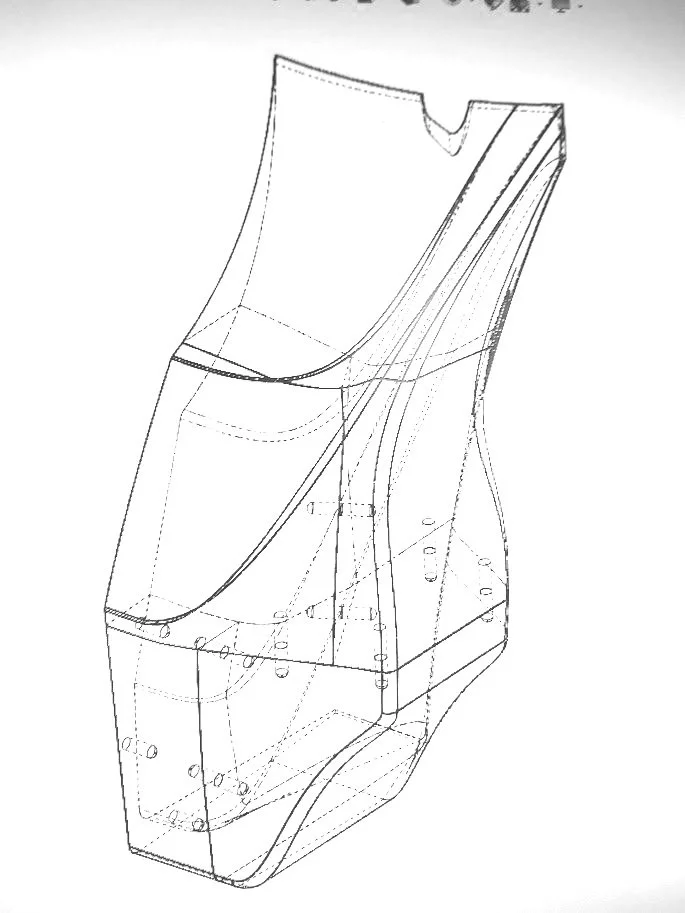

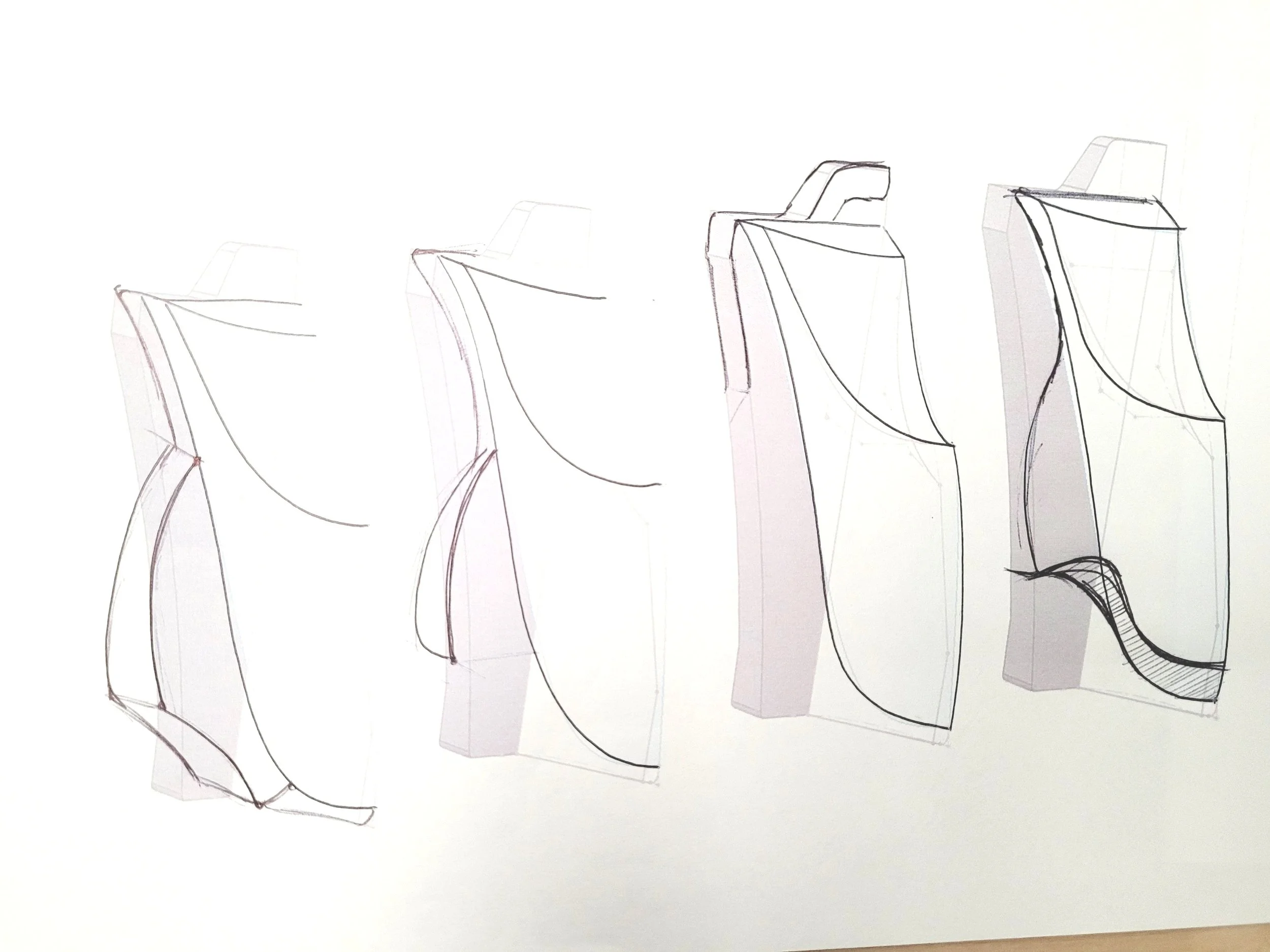

Roto MOULDING

The Mav Max XL fuel tank was a complex design. Maximizing volume, whilst limited to a 2 part tool with no inserts and a requirement for the tank to still be removable from frame with engine and trike in place meant a lot of foam modelling was required in development. Sketching proceeded surface modelling in Solidworks, and 3D printing before reviews, prototypes and production with the manufacturer.

This new tank will be key to the companies next generation core product.

INJECTION MOULDING AND ASSEMBLY

Completing the design for manufacture and assembly documentation on the hand held throttle with a factory in China was complicated for a safety critical product. A bowden cable, emergency stop buttons, cruise control function and engine start buttons all must be accurately assembled to document.

This project also lead to development of specialist throttle’s for military projects.

Fabrication

With extensive Titanium Fabrication happening out of house, there was always potential for errors and inaccuracies. As a member of the design team communications with the operations team and checking products on the production floor was key to ensure designs were to drawing.

NEXT GEN PRODUCT

major consumer design projects at parajet

UI / UX

internet of things

fabrication

machining

composites

mechanical

forging

industrial design

Updates to two major product lines at Parajet would ensure there was a well optimised model and sub-variant for every type of customer. One project was taken deep into conceptual stages with designing in composites, while the other titanium framed product was taken to sampling reviews and is due to be released soon.

Inline with the business strategy, these projects were all about pushing the product beyond what smaller companies in competition could achieve. Some key areas of focus included:

A new user experience system to give pilots more inflight data.

Update of mechanical designs for improved reliability and consistency.

Forged parts bringing down unit costs with enhanced performance.

Reducing expensive skilled labour requirement on in house assembly team.

Styling some components to appear vastly different than the rest of the market.

BRAND WORK

a new perception

Deconstruction of similarly positioned brands in different markets such as Trek and Poc helped pin point targets for the perception of the brand. Stepping away from it’s shed based origins, to achieve its business goals Parajet needed to identify as the most advanced, reliable and bench setting brand in the industry, with an ethos, voice and visual to match.

2003-2024

2024-

NEW visual

Brief: Modernize the brand, paying respects to the past whilst ensuring direction matches long term business goals, with a uniform look, feel and voice.

While I illustrated the new logo and emblem and drove the evolution of the brand values, more considered social media output and product branding, the work package also involved overseeing a junior graphic designer create new brand guidelines and visual elements such as video intros (below).

pARAJET dEFENCE

Defence projects were a huge part of working at Parajet. Noise signature reduction, novel powertrains and unmanned autonomous craft made interesting projects with new tech which has potential to enhance products on the consumer market.