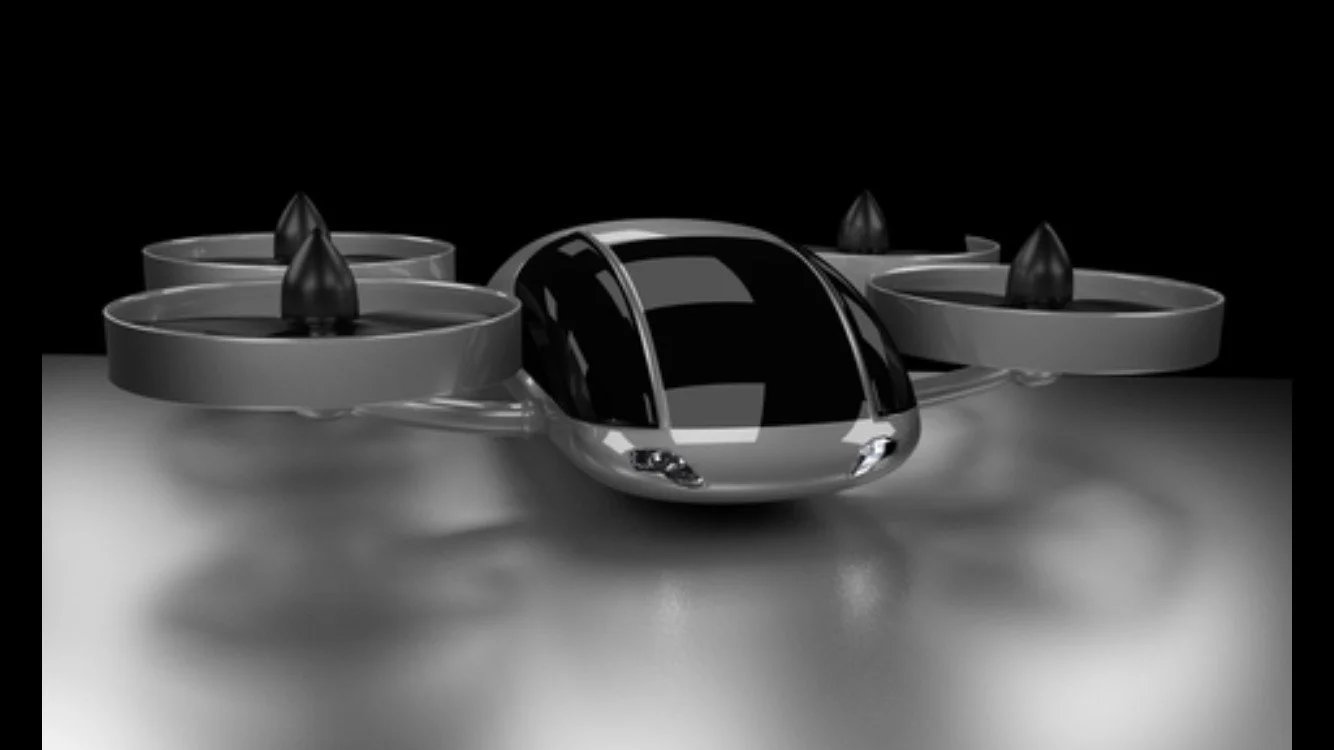

VRCO AIRCRAFT

A placement year in Electric Vertical Take Off and Landing (E-VTOL) aircraft start up provided a great insights into composites and the aeronautical engineering industry, working closely with F1 composites experts and ex-Prodrive and Rolls Royce engineers.

VRCO, Design Associate, Jun 2018 - May 2019

human factors

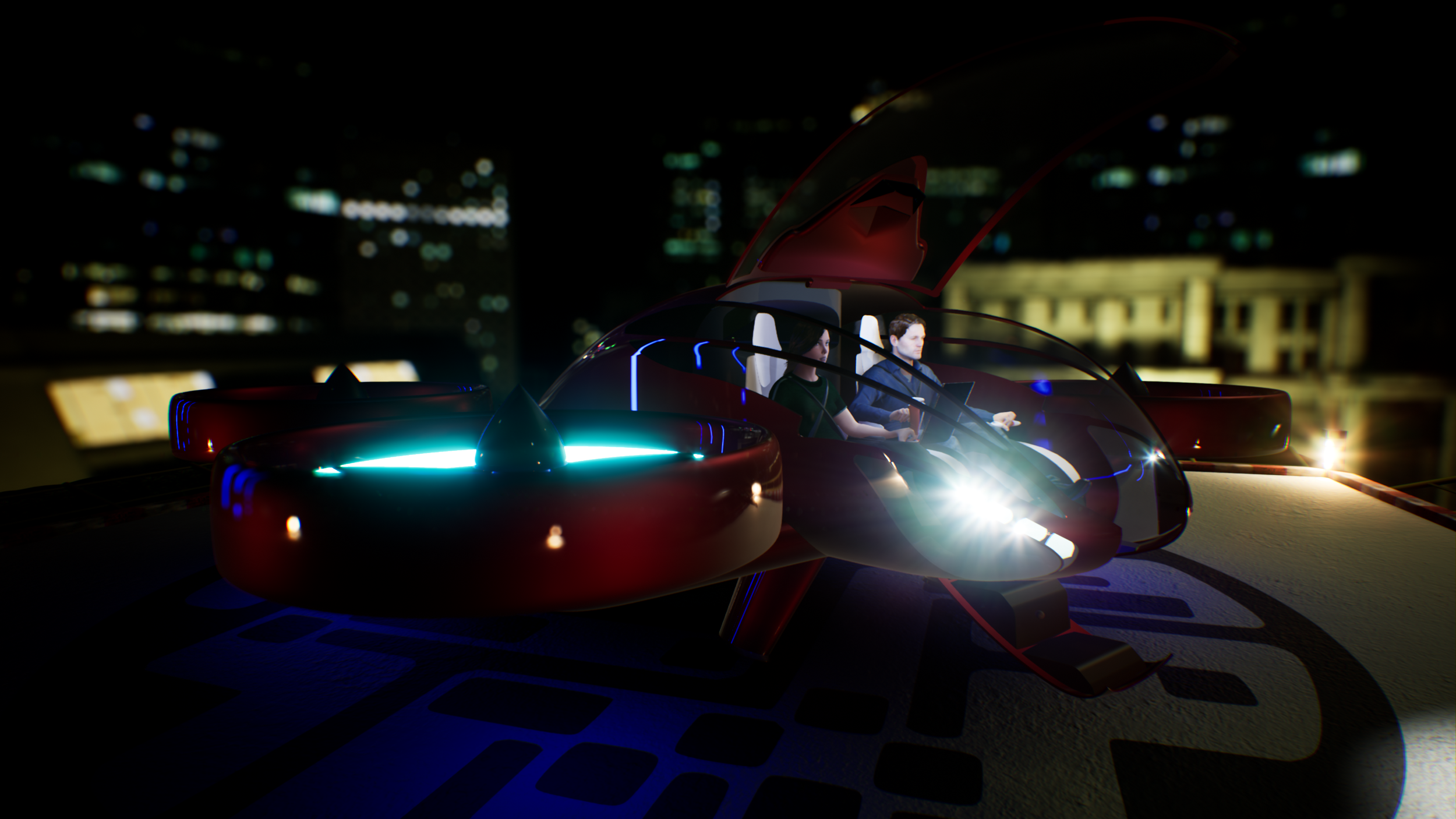

exterior design

interior design

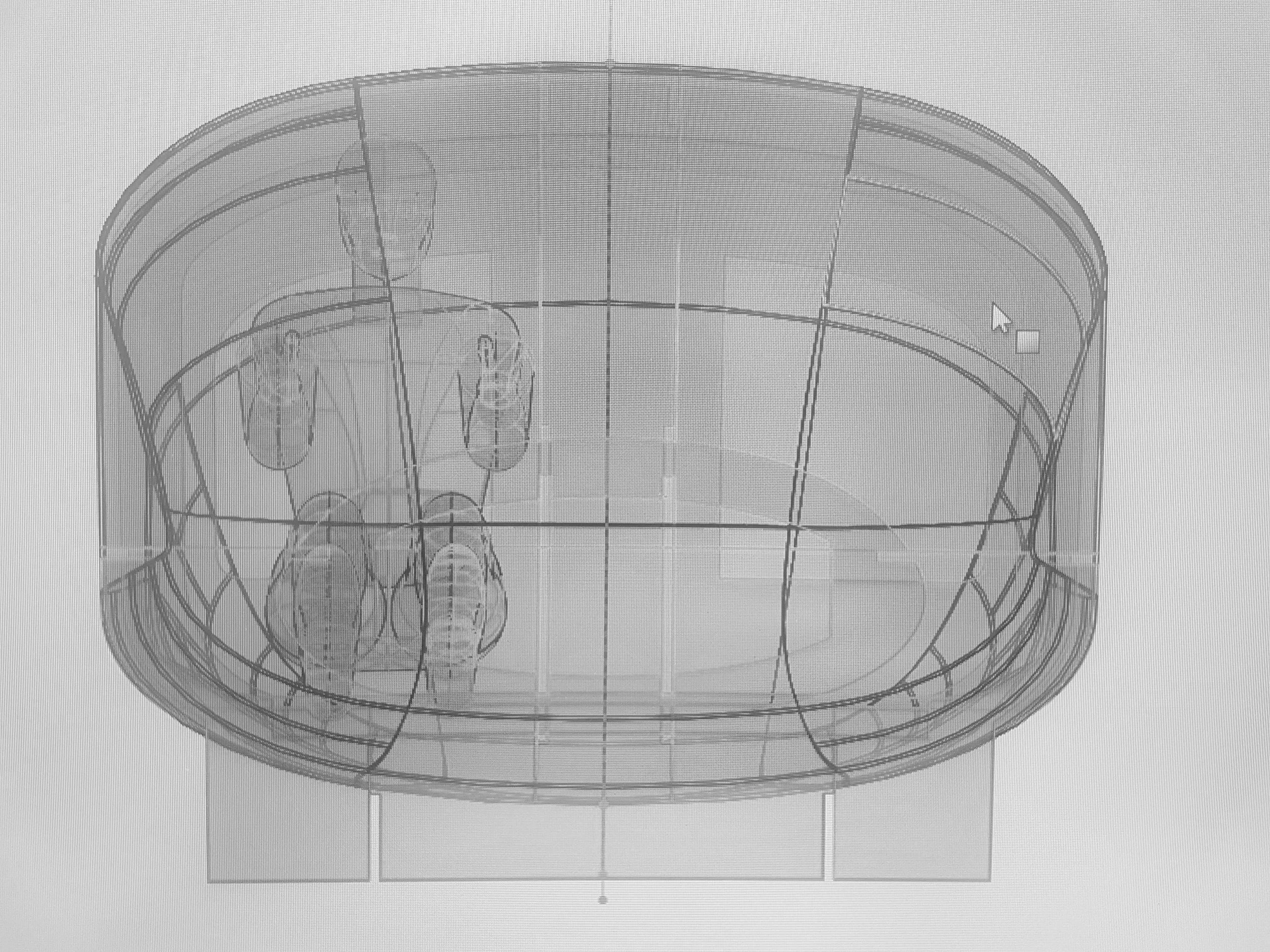

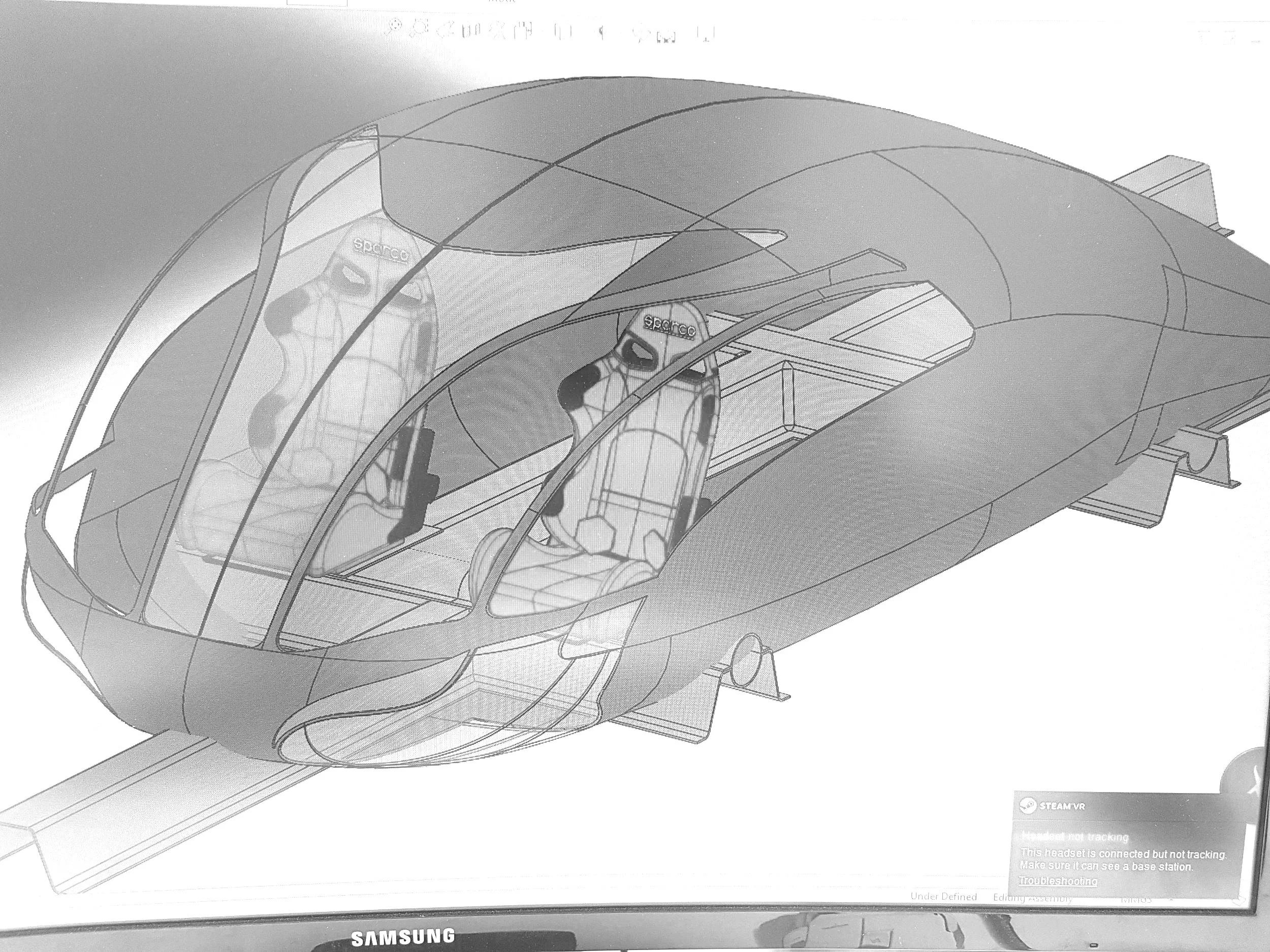

layout / structure

mechanical

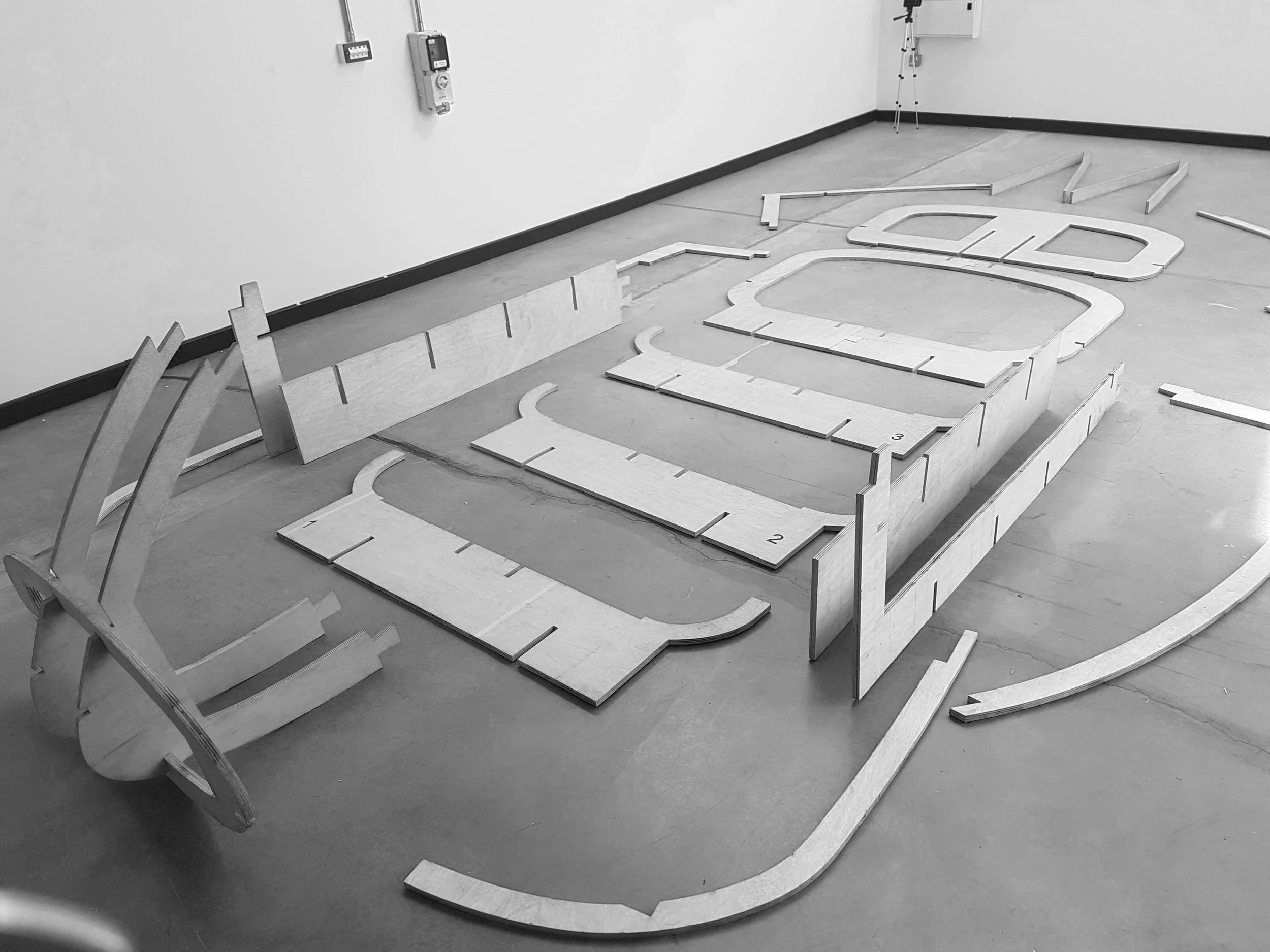

scale modelling

composites

visualisation

HUMAN FACTORS

At the start, the aircraft didn’t have a fully defined internal layout and a solution for human ingress / egress. Using a full scale plywood buck the feasibility of various solutions were reviewed. Working alongside a mechanical engineer, a clamshell solution was proposed which would allow pilot and passenger to enter and exit via the front of the craft. This concept could be extended to offer a lowering footstep as seen in the renders, however this would be at the potential compromise of structural integrity.

COMPOSITE PROTOTYPING

Working first at 1/10th and secondly at 1/4 scale, models were built to target testing different elements of the design. Using 3D prints to pull mould tools from, before laying up carbon, bag-pressing and baking in a large self-built oven, made the process as affordable as possible. Both pre-pregnated and wet-lay ups were performed for a range of components.